Micro Powder Grinding Mill with Precise Fineness Control and Higher

Whiteness

In order to protect the micro powder grinding mill, you need to

know how to start and stop the micro powder grinding mill:

Start the micro powder grinding mill:

1. Please ensure the voltage should not be less than 360V.

2. Please wipe out all the liters, and all the bolts and nuts are

all connected tightly.

3. Make sure the belt tightness is proper, and move the belt wheel

by hand, and mill wheel can rotate flexibly.

4. Ensure the valve handle in the blower air-in pipe is on the

“close” position.

5. Make sure the tightness of the elevator chain is ok.

6. Regular lubrication should be done according to the lubrication

table, and ensure there is no grease or oil leakage.

7. Feeding size into to the mill should be less than 10mm

8. Make sure the motor rotation direction is correct

9..Any metallic material should not be in the raw material. The users

had better install the iron eliminator by themselves.

Stop the micro powder grinding mill:

1. Stop the crusher until there is no material in the crusher

2. Stop the elevator until there is no material in the bucket.

3. Stop the feeding conveyor

4. Stop the mill until there is no material in the mill. This does

good to the next mill start and protection of the mill.

5. Stop the blower after stopping the mill in 30 seconds, and put

the extra air pipe valve on the “Close” position.

6. Stop the Classifier.

7. Stop the pulse-jet collector

As the raw material is ground between the roller and ring, the micro powder grinding mill noise is a little higher. This is normal for the micro powder

grinding mill and the noise should keep at a same level. If any

abnormal noise arises or the mill motor current increase suddenly

and difficult to decrease, please stop the mill and check

carefully. Maybe there is crack or iron in the grinding house.

After the installation, please do the test without any material.

Please note: the micro powder grinding mill should run less than 2 minutes without any material in the mill.

And then stop the mill to check whether every part is ok( no

overheating; no bolt looseness, no higher vibration for the mill).

After the test running, please feed some material into the mill for

grinding one hour. And then check whether every part is ok or not,

if yes, the mill can ran regularly.

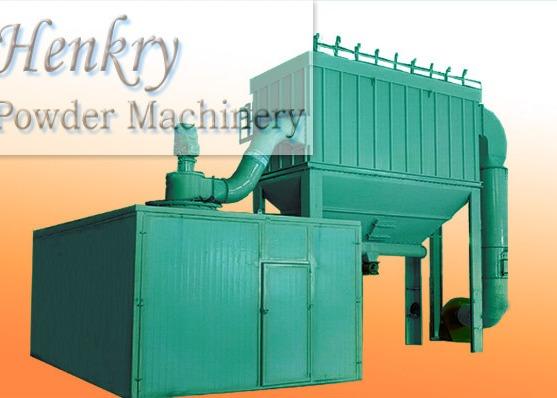

Structure of Micro Powder Grinding Mill:

The micro powder mill has the folllowing components: crusher,

elevator, hopper, feeder, classifier, mill, collector, blower and

electric control cabinet. And delivery and installation of the

whole micro powder grinding mill system is simple and easy to be

completed. As the micro powder grinding mill has been tested in the

factory, so the micro powder grinding mill can run as soon as the

installation is completely.

The motor drives the mill shaft and roller table go around by the

V-belt. The roller will rotate and revolve against the ring, which

will make the material into powder from the top level to the bottom

level. Classifier includes motor, coupling, shaft, vane wheel and housing. The motor controls the classifier wheel rotation speed. The faster

the rotation speed, the finer the powder and vice versa. The blower

includes housing, vane wheel, shaft, motor and support.

Special Features of Micro Powder Grinding Mill:

1. Perfect contact between rollers and ring: The arc or curved

surface increases their effective working surface and improves the

crushing efficiency. The rollers and rings contact surface and

shapes should be consistent and tightly fit, which is good to the

production of fine powder.

2. Improved hardness of rollers and rings: this not only guarantees

longer working life, but also the powder is not easy to be

contaminated.

3. Rotation speed of central shaft can be adjusted according to

customer’s requirement.

4. Pulse-jet Collector: 99.99% of the ultrafine powder can be

collected, which is also environment-friendly.

5. Constant temperature control system is adopted and the whole

design is also improved, so various additives can be put into the

mill to improved the application range of powder.

6. High quality casting technology to prolonger the working life of

roller and ring.

Technical Data of Micro Powder Grinding Mill:

| Mesh | 21 Rollers | 27 Roller |

| D97 | Output | Power | Output | Power |

| Kg/h | kw/h | Kg/h | kw/h |

| 300 | 3000-3500 | 43-50 | 5000-5500 | 43 |

| 800 | 2500-2800 | 54-60 | 3200-3800 | 62 |

| 1250 | 1500-1800 | 84-101 | 2300-2500 | 103 |

| 1500 | 1000-1300 | 116-152 | 2000-2300 | 118 |

| 2000 | 650-750 | 202-233 | 1500-1800 | 158 |

| 2500 | 600-650 | 233-253 | 1200-1300 | 197 |

| Total Power | 152kw | 237kw |